Aluminum Oxide

- Surface Preparation: Efficacious in releasing rust, paint, and further adulterations from metal surfaces, providing a clean substrate for coatings.

- Grinding and Cutting: Used in grinding wheels and cutting tools for machining metals, ceramics, & other hard materials.

- Blasting Media: Employed in sand blasting machine operations to clean and prepare surfaces for painting or welding.

- Lapping & Polishing: Provides fine finishes on components requiring high precision, such as optical lenses and semiconductor wafers.

- Non-Slip Surfaces: Incorporated into coatings to create non-slip exteriors in industrial and commercial settings.

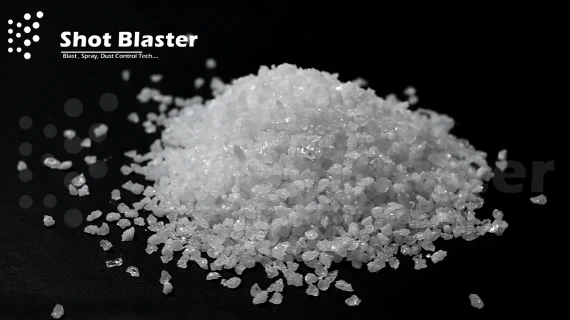

Introduction of Aluminum Oxide

Aluminum oxide abrasive is a favorably versatile and widely utilized material in assorted industries because of its excellent hardness, strength, or durability. Its applications vary from exterior preparation & finishing to cutting and grinding. Due to its strength or durability, makes aluminum oxide media at stripping & extracts impurities like rust, mill scale, and deteriorating paint from various substrates. Beyond these typical usages, it is even employed in specialized applications, including lapping, non-skid surfaces, headstrong coatings, & decorative applications. We also offer stainless steel shots, cast steel grits, walnut shells, PS balls, tungsten carbide grits, etc.

Aluminum oxide grit is a robust, cost-effective, and favorably versatile abrasive certain is widely employed across numerous applications. Aluminum oxide blast media is especially well-suited for both wet blasting machine and dry abrasive blasting machine operation, assembling it superior for exterior preparation and paint removal. Further, aluminum oxide media is a desired alternative for creating anchorperson patterns or achieving in-depth etching, which enhances coating & paint adhesion.

Aluminum Oxide Abrasive

The color of aluminum oxide abrasive especially influences its physical & chemical properties, creating it suitable for dissimilar tasks. White aluminum oxide blast media, comprehended for its excellent purity, is the best alternative for applications mandating contamination-free surfaces. In contrast, brown aluminum oxide, while narrowly less pure, remains positively efficacious and versatile, usually utilized for blasting, grinding, or widespread surface preparation.

In expansion to color, aluminum oxide grit size is a necessary factor in preferring the right aluminum oxide abrasive. Adequate grits are perfect for accessing grooves, cracks, and surface irregularities, delivering precision in exhaustive work. Larger grit sizes, however, are agreeably fitted for more uniform exteriors or tasks requiring less intricate finishing. Aluminum oxide blasting media is used in abrasive blasting machine operations to remove rust, aged paint, and old coating from rough surfaces.

Aluminum oxide is utilized for its hardness and strength. Its inherently arising form, corundum, is a 9 on the Mohs scale of mineral hardness. It is widely utilized as an abrasive, whichever contains a much less costly alternative for industrial diamonds. In nature, aluminum oxide abrasive is found as corundum. Industrial production mostly involves the Bayer process, where bauxite ore is refined to extract alumina. This process includes liquefying bauxite in sodium hydroxide, filtering impurities, and precipitating aluminum hydroxide, whichever is then calcined to produce aluminum oxide media. The production of aluminum oxide abrasive typically involves the following steps:

- Bauxite Refining: Bauxite ore is refined utilizing the Bayer process to make alumina (aluminum oxide).

- Fusing: The alumina is then melted in an electric arc furnace at temperatures exceeding 2,000°C (3,632°F).

- Crystallization: Upon cooling, the molten alumina solidifies into large crystals.

- Crushing and Screening: The solidified alumina is crushed & screened into various grit sizes proper for distinct abrasive applications.

Properties of Aluminum Oxide Abrasive

Aluminum oxide (Al2O3) is a chemical compound characterized by its elevated hardness, thermal stability, and chemical inertness. Key properties include:

- Hardness: With a Mohs hardness of 9, aluminum oxide is one of the hardest media available, assembling it effectively for cutting or grinding applications.

- Thermal Stability: It has an elevated melting point of approximately 2,050°C (3,722°F), allowing it to withstand extreme temperatures without degrading.

- Chemical Inertness: Aluminium oxide is resistant to chemical reactions, ensuring its effectiveness in various environments without risk of corrosion or degradation.

- Density: It has a specific gravity ranging from 3.9 to 4.1 g/cm3, contributing to its durability and effectiveness as an abrasive.

Types of Aluminum Oxide Abrasive

There are several kinds of aluminum oxide abrasives, each suited to distinct applications:

- White Aluminum Oxide: White aluminum oxide grit is a purer form with higher friability, assembling it is excellent for applications mandating minimal contamination and precise finishes, like in the medical and aerospace industries.

- Brown Aluminum Oxide: Contains impurities certain impart a brown color; it is difficult and appropriate for broad-purpose applications, whichever contain grinding and surface preparation.

- Pink Aluminum Oxide: These variants contain chromium oxide, enriching their toughness and durability, creating them appropriate for precision grinding of hardened steels.

- Black Aluminum Oxide: Includes a more elevated percentage of iron oxide, assembling it slightly softer and more proper for applications involving softer metals and wood.

Aluminum Oxide Uses

Aluminium oxide is a widely utilized material with applications that extend into everyday outcomes and specialized industries.

- In cosmetics, aluminium oxide could be found in items like blush, lipstick, & nail polish, wherever it enhances texture and finish. It is alike a key material in sandpaper, where its durable crystals provide effective sanding and polishing.

- Another unique usage is in billiards, wherever aluminum oxide is a major ingredient in the "chalk" applied to cue tips to enrich grip and precision. Additionally, aluminum oxide powder is utilized in CD/DVD scratch-repair kits to polish surfaces and restore functionality. Its amazing polishing grades also create it a common base ingredient in toothpaste, helping to clean teeth effectively.

- In medical applications, aluminum oxide plays a role in the production of hip replacements because of its strength or biocompatibility. It is likewise utilized as a dosimeter in radiation protection and therapy because of its ability to measure radiation exposure through optically stimulated luminescence properties.

- In elevated-temperature environments, aluminium oxide serves as a material for insulating furnaces, ensuring thermal stability and energy efficiency. Furthermore, in the fishing industry, most ceramic guides on fishing rods are assembled of aluminum oxide, as it provide smooth, durable rings for line movement.

Advantages of Aluminum Oxide Abrasive

The general usage of aluminum oxide abrasive could be attributed to several advantages:

- Durability: Its hardness ensures a long service life, reducing the frequency of replacement.

- Versatility: aluminum oxide abrasive media is eligible for a broad scope of materials, including ferrous & non-ferrous metals, wood, or plastics.

- Cost-Effectiveness: Offers a balance between performance and cost, creating it an economical alternative for numerous applications.

- Reusability: In blasting applications, aluminum oxide blasting media could be recycled numerous times before it degrades, enhancing its cost-effectiveness.

Aluminum Oxide Manufacturers in India

Shot Blaster is one of the best aluminum oxide manufacturers in India and aluminium oxide suppliers worldwide. Our aluminum oxide price is low compared to other industries. Aluminum oxide price also depends on the specification and types of aluminum oxide media. We also provide all types of abrasive media such as aluminum oxides, steel shots, steel grits, copper slags, garnet sand, glass beads, ceramic blasting beads, plastic abrasive media, etc, and also offer all types of abrasive blasting machines alike sand blasting machine, shot blasting machine, grit blasting machine, laser rust cleaning machine, granite engraving machine, and more.